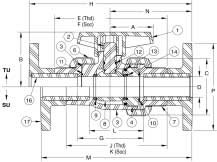

| PVC和CPVC材料Tru-Bloc球阀 True Union和Single Union PVC and CPVC Tru-Bloc Ball Valves True Union and Single Union |

| 22oC温度下150 psi非冲击性水,全端口(全流道) 150 psi at 73oF water–non-shock–full port 从开发True Union球阀以来,经过不断的测试和改进,已经形成了两种不同型号的阀门。True Union原先的结构是采用滑入阀体光滑的阀腔内阀座支架,而不是直接在阀体内固定。因此,在调节管接螺母的紧固度时,阀座对球体的压力就一直存在着。 As a result of continuous testing and improvements since the inception of the True Union Ball Valve, two distinct model changes have occurred. The original True Union design had a seat-carrier that slid into the smooth bore of the valve body, but it was not directly retained within the body. Thus, by adjusting the tightness of the union nut, the squeeze of the seats against the ball would be maintained. True Union球阀的第一次重大改进是型号B,引进了Tru-Bloc的设计理念,一种更加安全的性能。在这种设计结构下,采用通过螺纹固定在阀体的挡圈将阀座支架间接的固定在阀体内。在拆卸阀门的可“调节”端口的管接螺母和端口连接件时,这种改进消除了另一个端口的压力将内部部件和流体介质从阀门开口端口处吹出导致维修技工伤害或破坏周围设备的可能性。 The first major evolution to the True Union Ball Valve, Model-B, introduced the Tru-Bloc concept, a functional safety feature. With this design the seat carrier was indirectly held within the valve body by means of a retainer ring, which was attached to the inside of the body by threads. Should the union nut and end connector on the “adjust” side of the valve be removed, this change negates the possibility that pressure on the other side could blow the internal components and fluid medium out of the open valve end to injure the service mechanic and/or surrounding equipment. 现在的设计改进,型号C,保留了传统的True Union特点和Tru-Bloc设计理念。现在,一件式阀座支架用螺丝直接固定在阀体内,不再需要挡圈了。因此也不再需要准备外置阀座调节装置,因为位于阀座底下的凹槽的O形环,已经加进这种新式阀座支架。这种O形环槽的形状避免了在组装阀门期间,橡胶受到过度压力而损坏。此外,还可以通过阀座增能器的减压来自动调整阀座的磨损。 The current design evolution, Model-C, retains the traditional True Union feature and the Tru-Bloc concept. Now, a one-piece seat-carrier is screwed directly into the valve body, eliminating the need of a retainer ring. The provision for external seat adjustment is no longer required because an Oring, located in a groove beneath the seat, has been added to the new seat carrier. The shape of the O-ring groove prevents damage to the rubber from excessive compression during assembly of the valve. Yet automatic adjustment for seat wear can result from decompression of the seat energizer. 特点 Features

|

- 型号C的结构确保阀座后侧周围不会出现泄漏。在安装和测试Chemtrol的Tru-Bloc关闭阀门以后,连接到满罐的开口管道上将不会开始滴漏。

Model-C design features ensure no leakage around the back-side of the seats. Open piping attached to a filled tank will not start to drip-leak following installation and test of a Chemtrol Tru-Bloc shut-off valve. - 型号C的结构,在阀座支架下配置一个增能器O形环,使得这种阀门能够针对阀座磨损情况进行自动调整。在工厂组装期间,采用机械设备对阀座和阀门测试封装挤压进行调整。在安装期间,手动紧固管接螺母用来压紧Chemtrol阀门的表面密封。

Model-C design, with an energizer O-ring beneath the seat-carrier, enables the valve to automatically adjust for seat wear. Adjustments for envelope squeeze on seats and valve testing are done by machine during factory assembly. Upon installation, a hand-tightened union nut serves to compress the face-seal of a Chemtrol valve. - 全端口(全流道)结构产品使得流体限制降到最小,可能的压降也降到最小。

Full port design produces minimum flow restriction with the lowest possible pressure-drop. - 阀门在制造和组装过程中,没有暴露在含硅酮的环境中。

Valves are manufactured and assembled without exposure to silicone compounds. - 独特的橙色手柄可以远距离指示“启闭”和流体方向。手柄顶部模铸的箭头指示旋转方向,使得操作人员容易在90o角内操作。由于实际应用中有时需要拆卸手柄,D形环阀杆平面指示“启闭”状态,阀杆顶部的模铸箭头指示流体方向。

Distinctive orange handle indicates “open/close” and direction of flow at a distance. And molded-in arrows on top of the handle dictate rotational direction to personnel for easy operation within 90o stops. For applications requiring handle removal, the D-ring stem flats indicate "open/close" and a molded-in arrow on top of the stem indicates flow direction. - 参阅Chemtrol阀门执行机构指南,选择电动或气动执行机构及附件,包括用于阀门现场安装或工厂组装的塑料外壳和塑料安装组件。

Refer to the Chemtrol Valve Actuation Guide for full selection of electrical and pneumatic actuators with accessories, including plastic housings and plastic mounting kits for field or factory assembly to valves.

Notes

参阅第2页的“部件材料清单”。如果需要了解更多的材料选择,请参阅第1页的“材料”。适用于球阀的“执行机构安装参数”和“备选附件”的完整清单请参阅第21页及以后的内容。这些阀门的“安装和维护指南”内容在第8页。如果需要额定压力-温度的特殊关系,请参阅第33页的“工程技术参数”。如果需要“Chemtrol阀门标准”,请参阅第35页。

See page 2 for a list of Components and Construction Materials. For more insight into the selection of materials, refer to Materials, page 1. Actuation Mounting Data and a complete listing of Optional Accessories for ball valves begins on page 21. Installation and Maintenance Instructions for these valves appear on page 8. For specific relationships of pressure vs. temperature ratings, refer to Engineering Data, page 33. For Chemtrol Valve Standards, see page 35.