安装和维护指南

Installation and Maintenance Instructions | True Union球形止回阀,底阀,和排气阀

True Union Ball Check, Foot, and Vent Valves

| | |

安装

Installation | Chemtrol管接头端口止回阀/底阀可以配置承插,螺纹,或法兰端口连接件。在连接管接头阀门时,或者在进行法兰连接时,绝对不要连接到已经连接在阀体上的端口连接件上。首先从阀芯上拆卸管接头螺母和端口连接件。为了防止管接头螺母的意外事故,在连接到端口连接件之前,(先从最小的阀腔开始)将它滑到管道或管嘴-法兰中枢上(当进行法兰连接时)。

Chemtrol union-end check/foot valves can be fitted with socket, threaded, or flanged end connections. When joining union-end valves, or when flanging end connectors, never make the joint to the end connectors while they are attached to the valve body. Remove the union nuts and end connectors from the valve cartridge first. In order to prevent mishaps with the union nut, slide it (smallest bore first) over the pipe or nipple-and-flange hub (when flanging) before making the joint to the end connector.

止回阀应该安装在距离泵的排泄口至少4英尺的位置。如果流体出现比较严重的湍流,可能导致球体震动和内部损坏。此外,为了保持良好的机械性能,Chemtrol产品流体流量的最高临界值是每秒五英尺。

Check valves should be installed at least four feet from the discharge side of a pump. Ball chatter and internal damage may result if fluid flow is too turbulent. Also, in keeping with good mechanical design practice, the upper threshold of fluid flow recommended from Chemtrol products is five feet per second.

警告:这种阀门应该安装在垂直或水平位置(请参阅上一页关于所需的最小阀座头),但是,阀腔上的模铸流向箭头必须安装在与流体流向一致的方向,这样回流就会被止住。由于所有球体材料的规定比重都大于1.0,球形止回阀不能作为排气阀进行反向安装,使得球体漂浮进阀座位置。

Caution: The valves may be installed vertically or horizontally (refer to the preceding page for minimum seating head requirements), but the molded-in flow arrow on the valve cartridge must be installed in the direction of the fluid flow such that reverse flow will be checked. Since the specific gravity of all ball materials is greater than 1.0, the ball check valves cannot be inverted to function as a vent valve by allowing the ball to float into seating position.

螺纹连接端口–参阅《Chemtrol热塑塑料管道技术手册》中的塑料螺纹连接指南,了解正确的连接技术。警告:不要过分紧固螺纹。一般情况下,当手旋转感到紧的时候,如果需要的话,采用适当的固定扳手在多旋转一到二圈,也就足够了。(ANSI B1.20.1定义,对于DN50以下的阀门,手紧为4到5圈螺纹,对于DN50以上的阀门,则为5到6.75圈螺纹。)

Threaded-End–Refer to the plastic thread joining instructions in the Chemtrol Thermoplastic Piping Technical Manual for proper joining techniques. Caution: Do not overtighten threads. Usually, one to two turns beyond hand-tight using a suitable strap-wrench, if necessary, is sufficient. (ANSI B1.20.1 defines hand tight as 4 to 5 threads for sizes through 2" and 5 to 6 3/4 threads for sizes over 2".)

承插端口阀门–参阅《Chemtrol热塑塑料管道技术手册》中的液状粘固剂连接指南,了解正确的连接技术。警告:不要让紫色底漆或液状粘固剂流进接触到端口连接件的密封面或阀门的内部部件。

Socket-End Valves–Refer to the solvent cement joining instructions in the Chemtrol Thermoplastic Piping Technical Manual for proper joining techniques. Caution: Do not allow purple primer or solvent cement to come in contact with the sealing face of the end connectors or internal components of the valve.

对于PP或PVDF阀门,参阅《Chemtrol热塑塑料管道技术手册》中的热熔合连接指南,了解正确的连接技术。警告:Chemtrol阀门需要特殊的热熔合工具来进行正确的连接。这些工具可以在《Chemtrol连接件指南》中找到。

For PP or PVDF valves, refer to the heat fusion joining instructions in the Chemtrol Thermoplastic Piping Technical Manual for proper joining techniques. Caution: Chemtrol valves require special heat fusion tools to make proper connections. These tools can be found in the Chemtrol Fitting Guide.

法兰端口阀门–参阅《Chemtrol热塑塑料管道技术指南》中的塑料法兰连接指南,了解正确的连接技术。警告:不要让法兰连接过紧。

Flanged-End Valves–Refer to the plastic flange joining instructions in the Chemtrol Thermoplastic Piping Technical Manual for proper joining techniques. Caution: Do not overtighten flanges.

阀腔–经过适当的连接养护时间后,端口连接件可以连接到阀腔上。O形环提供阀门面和端口连接件面之间的密封。在端口连接件之间滑入阀腔前,要确保这些O形环清洁干净,并且位于正确的槽内。将管接头螺母滑入端口连接件上,并且螺纹对上阀腔的螺纹,手紧后就停止。

Valve Cartridge–After allowing the proper joining curing time, end connections may be joined to the valve cartridge. O-rings provide the seal between the valve faces and the end connector faces. Ensure that these O-rings are clean and in their proper grooves before slipping the valve cartridge between its end connectors. Slide the union nuts over the end connectors and screw onto the valve cartridge threads, no more than hand-tight.

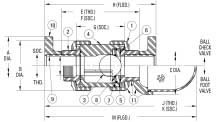

底阀连接–可提供底阀滤网壳组件在现场将球形止回阀转换为底阀。这种组件,正如上一页所讨论的,以及本页的剖视图内所见,是安装在标准Chemtrol球形止回阀的供应侧上,更换管接头螺母和端口连接件。通常底阀是安装在一个开口罐里,或泵的吸入一侧的液体坑里。它的功能是过滤进入泵的碎片。

Foot Valve Conversion–Foot valve screen housing assemblies are available to convert ball check valves to foot valves in the field. The assemblies, discussed on the preceding page and seen in the split-view drawing on this page, are to be installed on the supply side of a standard Chemtrol Ball Check Valve, replacing the union nut and end connector. Foot valves are normally installed in an open tank or sump on the suction side of a pump. Its function is to screen debris from entering the pump.

|

| | 排气阀连接–标准Chemtrol球形止回阀内的球体设计初衷就是要使其的密度大于流体介质的密度。当安装在垂直状态(阀座朝下 - 阀体上的箭头指向正常的流体流向)到水平位置,为了防止流体流动停止(如泵停止时)出现倒流,球体上的重力使其浸入在流体和阀座的密封里。但是,机械设计人员有时要求空气或气体从管道系统或流体储存系统的容器中排出,而不是在通风管道处的流体止回。当流体从系统或容器中排空时,排放阀必须打开以防止出现真空现象。现场将止回阀转换为具有排放功能的阀门,要求用聚丙烯球更换标准球,这样就可以浮在水里或密度更大的流体里。参阅上一页的《阀门结构部件》表和本页的图。排放阀必须安装在倒置垂直位置(阀座朝上 - 阀体上的箭头指向正常排气的相反方向)。警告:漂浮球体也必须具有耐流体介质腐蚀的化学特性。强氧化剂可能会使聚丙烯球体出现应力裂纹(如,漂白剂,浓缩硫酸或硝酸)。

Vent Valve Conversion–The ball in a standard Chemtrol Ball Check Valve is intended by design to have a greater density than the fluid medium. When installed in the upright (seat down – arrow on body pointed in direction of normal flow) to horizontal positions, gravitational force on the ball allows it to sink in the fluid and seal at the seat in order to prevent back-flow when directional flow is ceased (e.g., pump stops). However, the mechanical designer sometimes wants air or gas to be vented from a piping system or vessel as fluid fills the system, but to check flow of fluid beyond the vent tube. As fluid is evacuated from the system or vessel, the vent valve must open to prevent formation of a vacuum. The field conversion of the check valve to the venting function requires the replacement of the standard ball with a polypropylene ball, which will float in water or fluids of greater density. See the Components of Valve Construction chart on the preceding page and the drawing on this page. A vent valve must be installed in the inverted vertical position (seat up – arrow on body pointed in opposite direction of normal venting). Caution: The floater ball must also be chemically resistant to the medium. Good oxidizers may stress crack the polypropylene ball (e.g., bleach, concentrated sulfuric or nitric acids).

调整–不需要对阀座进行调整。但是,每个管接头螺母在端口连接件上必须具有适当的压力,以防止在阀体的每个端口的O形环面密封上出现壳裂。显然,如果O形环已经正确安装在它们的槽内,则管接头螺母的进一步紧固能够阻止这些位置的壳的泄漏。如果无法手动调整螺母,则可以采用适合的固定扳手。警告:不要过紧。通常在恢复阀门的密封状态后,在多增加1/4转或更少的调整就足够了。

Adjustment–Adjustment to the seating action is not required. However, each of the union nuts must apply adequate force on its end connectorto prevent shell leaks at the O-ring face seals on each end of the body. Obviously, further tightening of the union nuts should stop shell leaks at these locations if the O-rings have been properly seated in their grooves. If unable to adjust the nut by hand, a suitable strap-wrench may be used. Caution: Do not overtighten. Usually, 1/4 turn or less adjustment is sufficient to restore the valve to sealing condition.

维护

Maintenance

如果一个阀门需要维修,则在阀门的两侧对系统进行减压和排放。松开阀门的管接头螺母,并将其滑回到端口连接件上。为了减少停工时间,最好是准备好阀腔更换件,来安装在需要维修的部件的位置上。按照下列步骤拆卸阀腔:

Should a valve need repair, depressurize and drain the system on both sides of the valve. Loosen the valve union nuts and slide them back over the end connections. To minimize downtime, it may be advisable to have a replacement valve cartridge ready to install in place of the one to be repaired. Disassemble valve cartridge as follows:

- 将柔软的、钝的工具插入阀门的下游端口,将球体和密封托架从阀门的上游端口推出。

Insert a soft, blunt instrument into the downstream end of the valve and push the ball and seal carrier out of the upstream end of the valve. - 检查所有部件,用新的替换部件来更换任何损坏或磨损的部件。如果阀体损坏,我们建议更换整个阀腔。

Examine all parts and replace any damaged or worn components with new replacement parts. If the body is damaged, we recommend replacing the entire valve cartridge.

在第15页上可以找到Chemtrol管接头端口类型球形止回阀和底阀的“更换部件清单”。在选择更换部件前,应该正确识别阀门。警告:阀门维修只能由有资格认证的的维护人员进行。与离您最近的Chemtrol经销商联系,了解所需的进一步信息。

A Replacement Parts List for Chemtrol union-end type ball check and foot valves may be found on page 15. The valve should be properly identified before selecting replacement parts. Caution: Valve repair should only be performed by qualified maintenance personnel. Contact your nearest Chemtrol distributor should further information be required.

阀座–位于阀体阀座内槽的标准O形环会影响球体和阀体阀座之间的流体密封(倒棱肩)。这种阀座密封包括在O形环组件内,在“更换部件清单”中可找到。

Valve Seat–The fluid seal between the ball and body seat (chamfered shoulder) is affected by a standard O-ring located in a groove in the body seat. This seat seal is included in the O-ring kit, which is identified in the Replacement Parts List.

注意

Notes

参阅第15页的“结构材料和部件”清单。要更深入了解材料的选择,请参阅第1页的“材料”。要了解压力与温度之间的特定关系,参阅第33页的“工程技术参数”。要了解“Chemtrol阀门标准”,参阅第35页。

See page 15 for a list of Components and Construction Materials. For more insight into the selection of materials, refer to Materials, page 1. For the specific relationship of pressure vs. temperature, refer to Engineering Data, page 33. For Chemtrol Valve Standards, see page 35.

| 要选择适用于您的应用领域的Chemtrol阀门,参考《Chemtrol耐化学性能指南》

To determine suitability of Chemtrol Valves in your application, consult the Chemtrol Chemical Resistance Guide. |

|